Two teams of researchers from the Massachusetts Institute of Technology (MIT) have developed sensors for soft robots. The first research is based on pressure sensors, the other on cameras, and artificial intelligence.

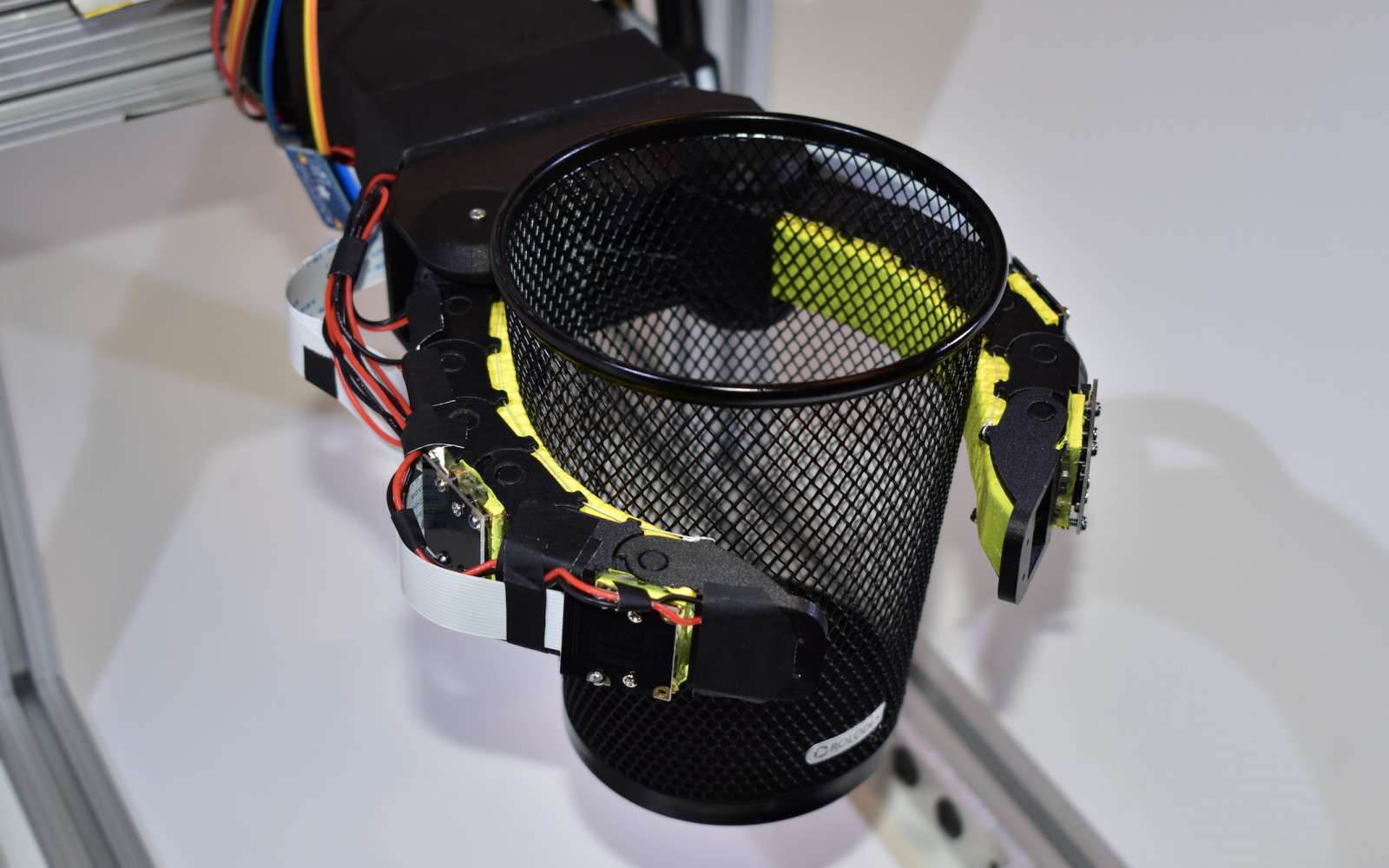

The soft robotics focuses on machines created from soft materials. These robots are not only much less dangerous for the people who workaround, but are also capable of more delicate handling. One of the obstacles to their development is the difficulty of integrating sensors into it. At the Massachusetts Institute of Technology (MIT), researchers from the Computer Science and Artificial Intelligence Laboratory (CSAIL) have just announced two advances in two different articles.

The first research takes up a previous project from 2019. The tool, which has a suction cup shape, delicately folds around the object to be picked up, but can lift more than 100 times its weight. To improve accuracy, the researchers have equipped with sensors tactile composed of small balloons in latex connected to pressure sensors. The robot is thus not only capable of lifting a potato chip without crushing it, but can also identify what it is picking up.

The deep learning to identify the deformations robotic fingers

Another group of researchers created a soft robotic forceps called GelFlex. This uses on-board cameras to observe deformations of the fingers. The team used deep learning and neural networks to identify the objects caught and predict the angle of flexion of the clamp. Researchers report an average positioning error of less than 0.77 millimeters, less than a human finger.

Both projects were presented virtually at the ICRA 2020 robotics congress. In both cases the sensors still need to be refined, but they could lead to more versatile and precise soft robots . This same technology could also be used to create more efficient and lightweight soft robotic prostheses .