The trend of “ do it yourself ” (DIY), “free”, digital and the collaborative economy, already made it a leading economic alternative. With factories shutdown linked to the Covid-19 health crisis and thinking about ways to produce differently, (creative) makers, their FabLabs, their minds and their 3D printers are more than ever in the spotlight. How to integrate them and what can be their influence or their role on the future of the industry?

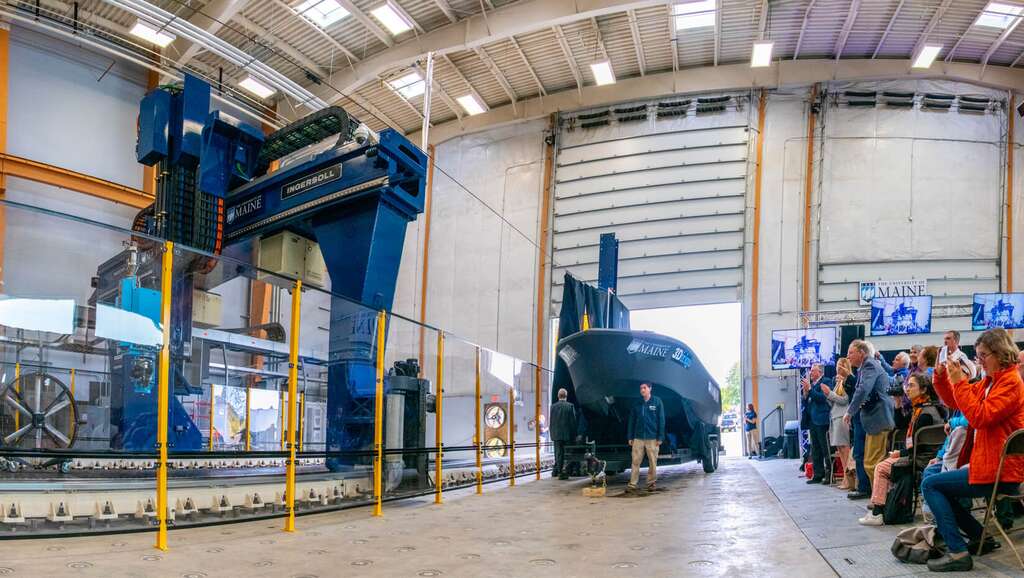

Code name: makers for life . Goal ? Design and mass produce a robust respirator for Covid-19 patients . “MakAir” will cost € 1,000 each, or 10 to 45 times cheaper than existing ones, and will be manufactured using 3D printers, based on plans distributed free of charge! Part of the idea of a young engineer from Nantes who wanted to be “useful”, the process which has since brought together hundreds of creators and experts (professors, manufacturers like Seb or Renault, engineers, researchers, etc.) has received from the money and the support of the ECA. One example among many, which illustrates the ability of makers to produce massively, outside of the classic model.

With an agility to make the most beautiful R&D cells or even startups fade with envy, will the health crisis allow the industry and its factories to be reinvented, thanks to makers?

Where does the maker movement come from and what place does it occupy?

First appearing in the United States in the early 2000s, the movement has since spread around the world. Community and collaborative, makers, or creatives, mix the digital culture of free and open source , with that of more traditional know-how.

Steeped in Do it Yourself , the current Géo Trouvetou came together with certain principles and values including:

- knowledge sharing and learning by “doing”;

- the dissemination of files, maps digital ;

- pooling of manufacturing resources;

- the creation of collective meeting and working spaces (makerspaces, fablabs, etc.).

Support (forums, blogs , journals, etc.), the thousands of open workshops and events, such as the Maker Faire , also contribute to spreading the maker culture, which some describe as “the factory of change ”. The maker movement blurs the boundaries between leisure and work, non-market and market, local and global, crafts and industry. It is also clearly mobilized for the general interest and positions the maker movement as a major societal phenomenon , claiming a place in the face of the inadequacy of the current productive system.

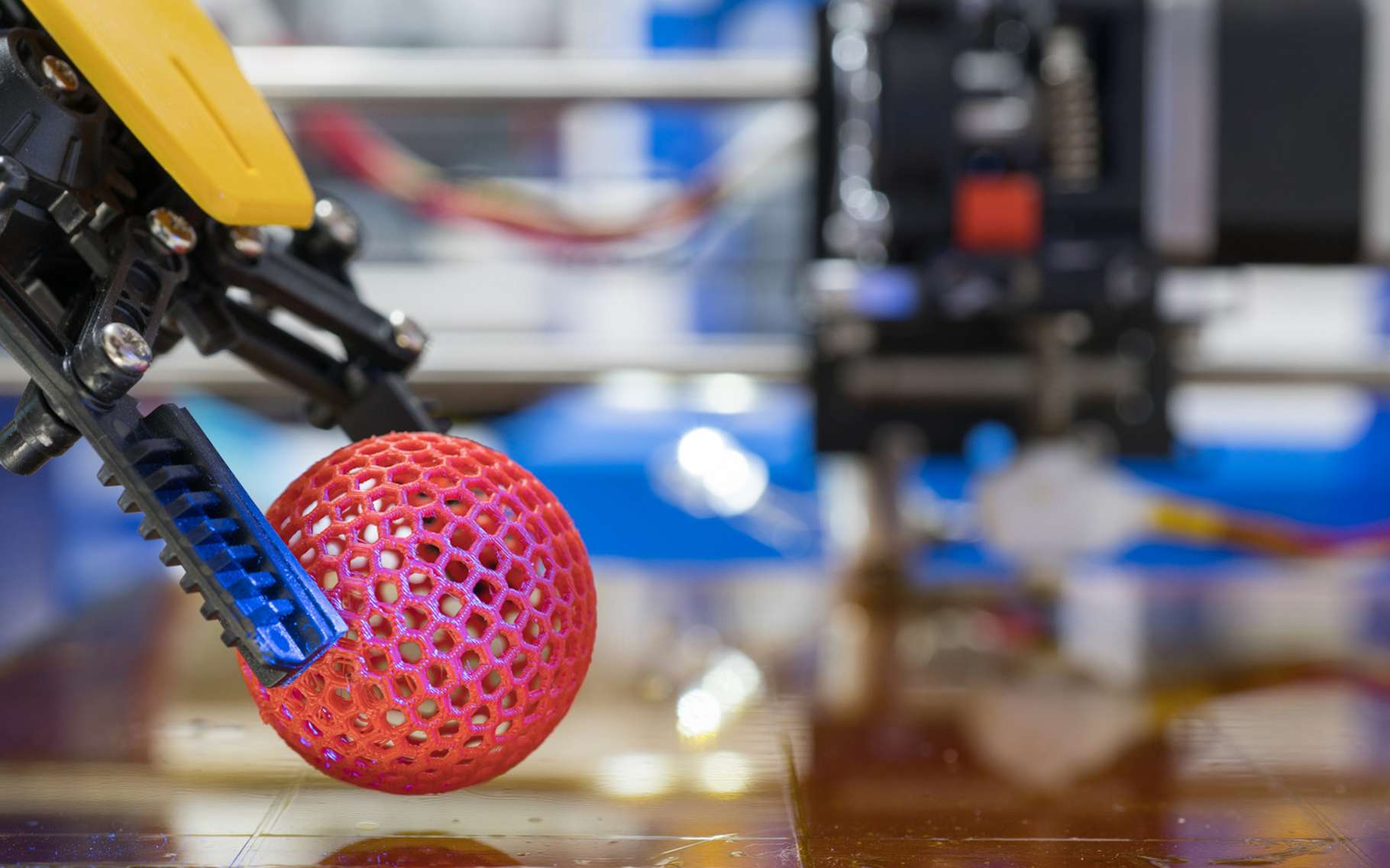

Hybrid and multifaceted, with tutorials and short improvisations between developers, exchanges of practices or know-how, makers also attract companies, who do not hesitate to send their engineers or technicians, or even to collaborate on the creation of prototypes or small series of parts.

When the Covid-19 illustrates the power of makers to federate and industrialize

The Covid-19 crisis and the lack of protective medical equipment are a notable example. Collaborative initiatives and co-development of products intended for the medical and health sector were numerous, all over the world, from March 2020 . The makers rely on their culture of collaboration and open innovation, to decompartmentalize and mobilize the most relevant resources. They “break the industrial codes” to achieve their goal. From the diving mask diverted into a respirator to printed valves, contactless gel dispensers or protective visors, the ambition is to meet a need. Quickly. And massively thanks to the collective.

Multiplication of initiatives and online discussion groups, almost instant responses from makers and outside official processes have made it possible to provide caregivers with protective equipment and medical instruments. The platform of the Paris Covid 3D Hospitals has given a start to recognition for their unprecedented mobilization, by approving models without patents from open research to distribute them with secure manufacturing and distribution specifications.